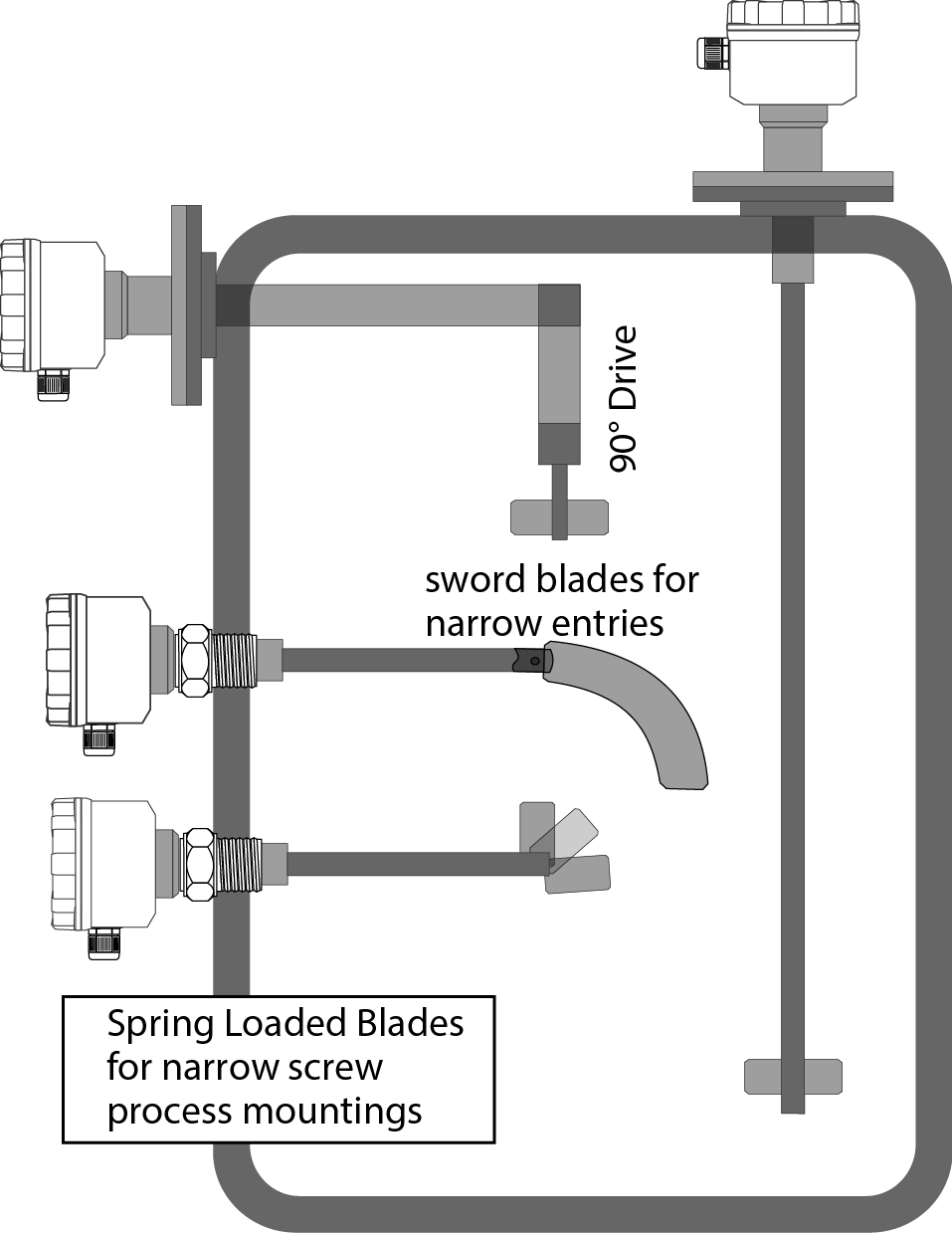

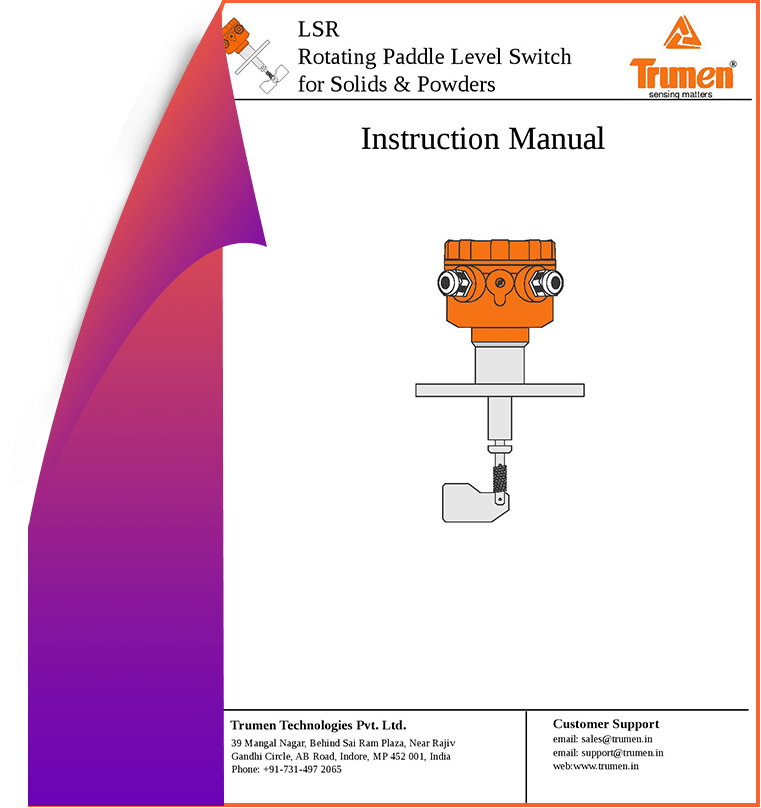

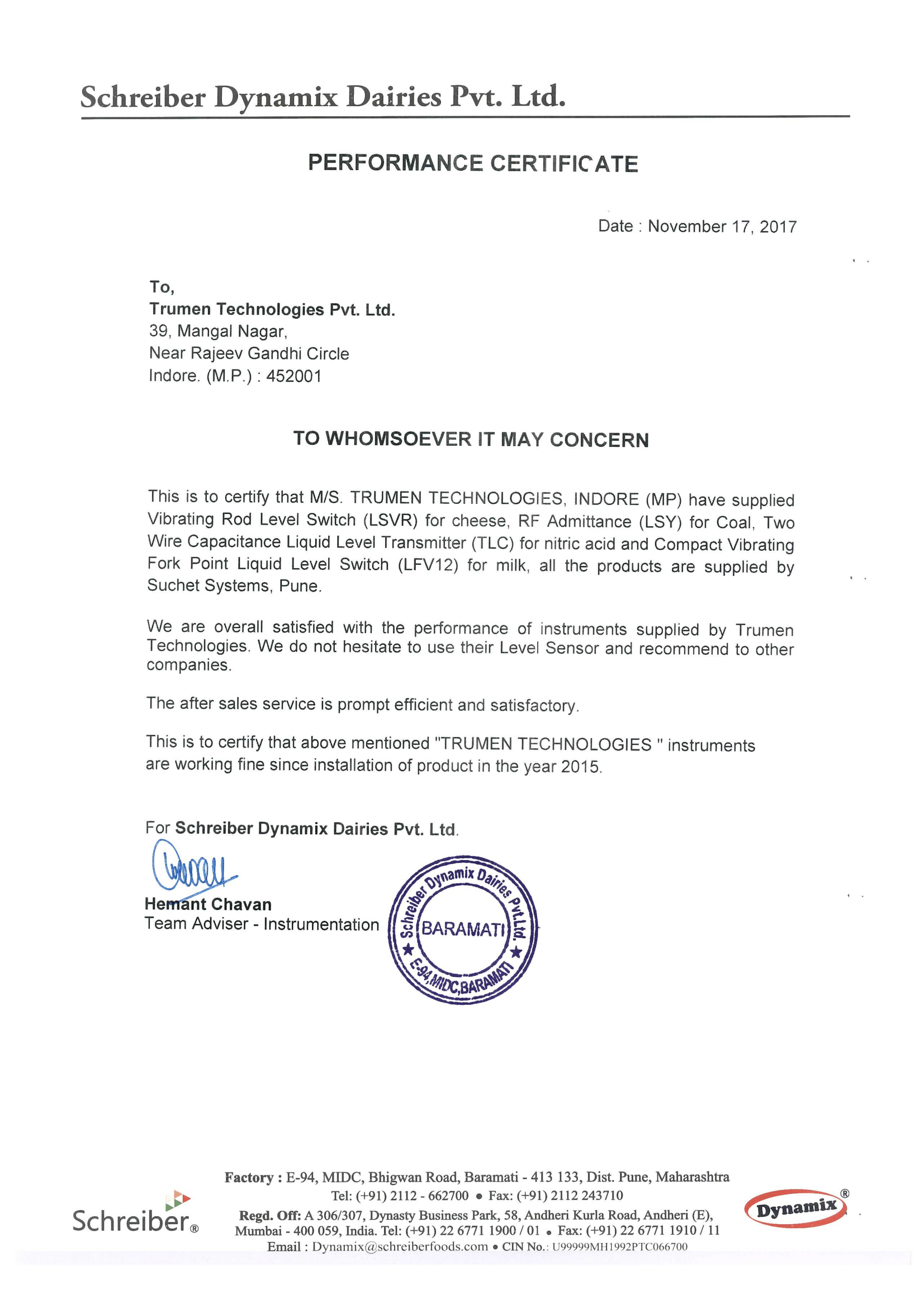

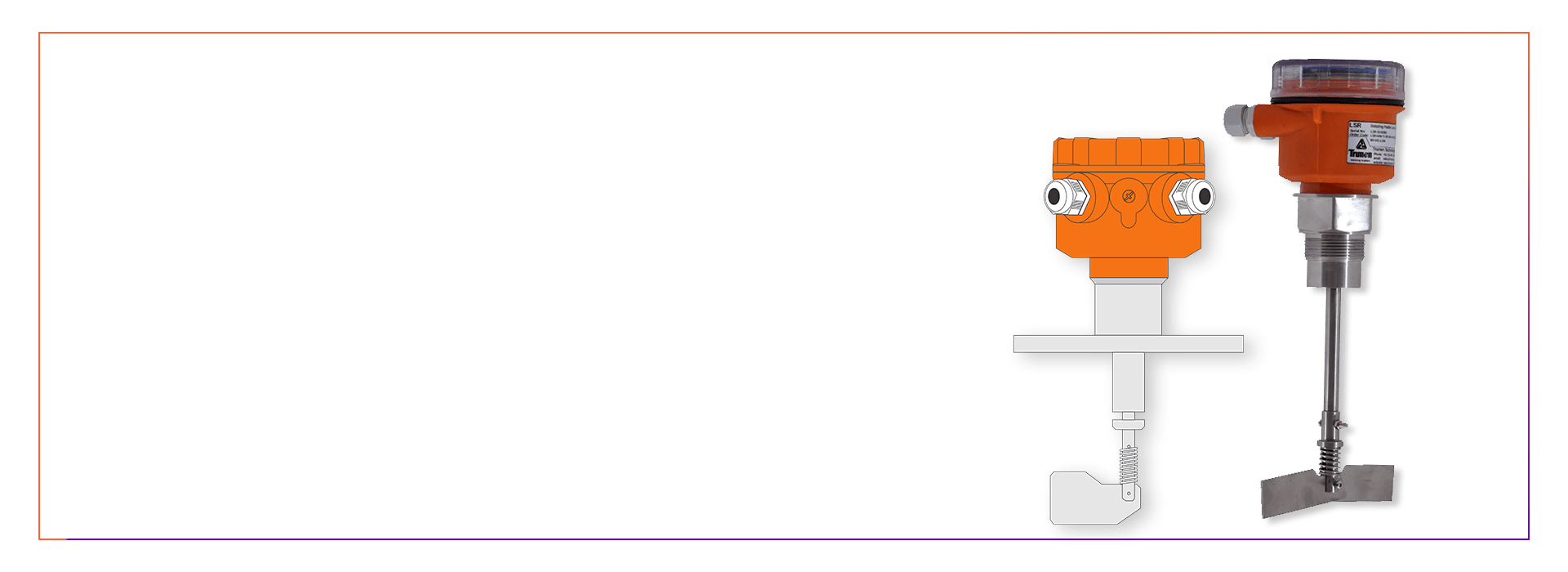

About LSR

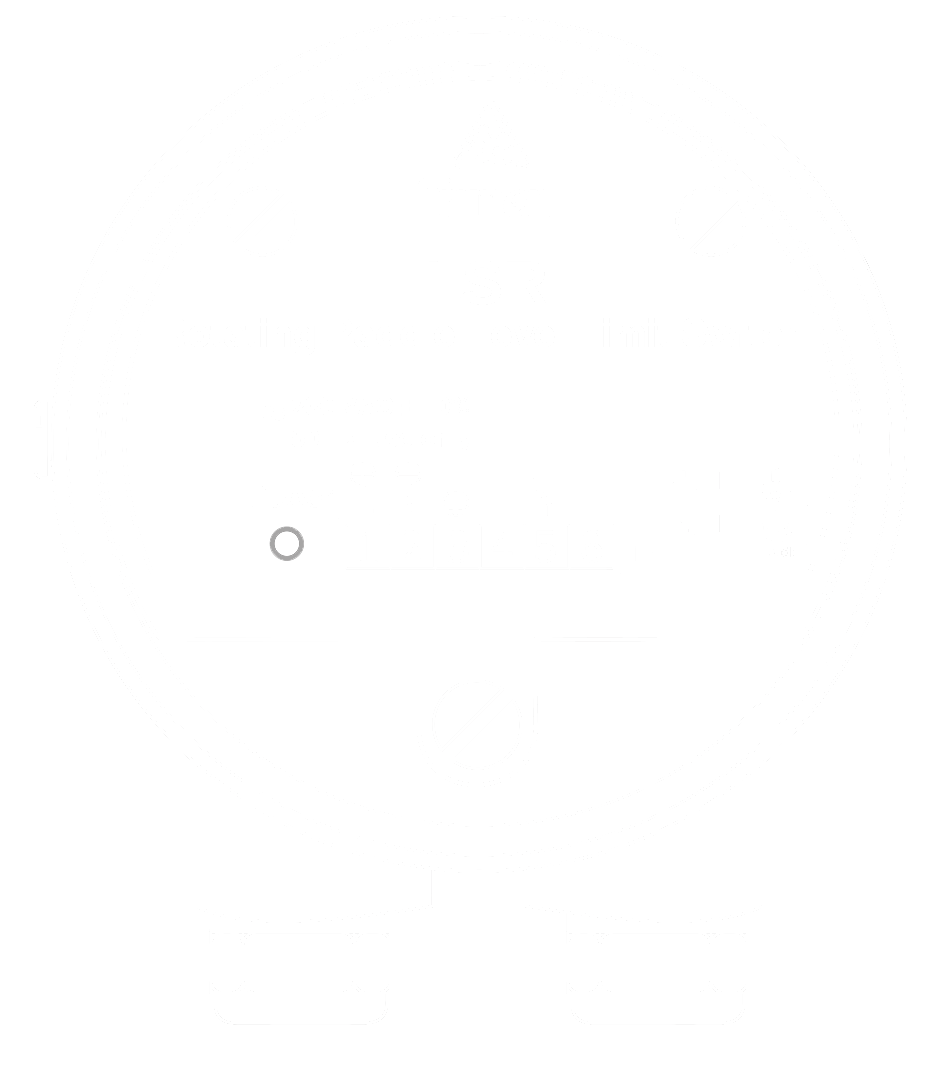

Trumen Rotating paddle type level switch Model LSR are spring loaded eccentrically driven rotating vanes or blades, which rotate at a slow roational speed of 3rpm maximum, using a geared motor.

About Trumen

Trumen came into existence in 2009 and initially started with manufacturing of Tuning Fork Level Switches for liquid and solid applications. With time, the manufacturing range increased with addition of Capacitance Level Transmitter & Capacitance Level Switches, RF Admittance Level Switches, Rotating Paddle Level Switches, Conductivity Type Level Switches, Vibrating Rod Level Switches, Hydrostatic Level Transmitter, Radar.

Know More

Features

- Simple construction.

- Calibration-less operation.

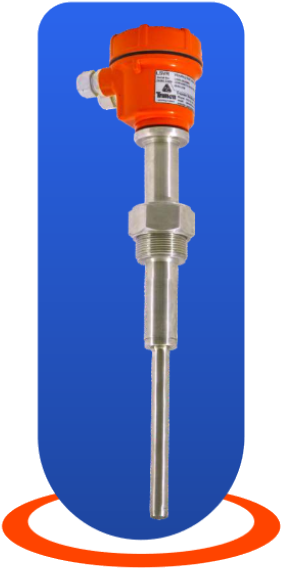

- Customized process connection threaded / flange etc.

- Various paddle design depends on material bulk density.

- Weather proof & flame proof protection with aluminium or polycarbonate enclosure.

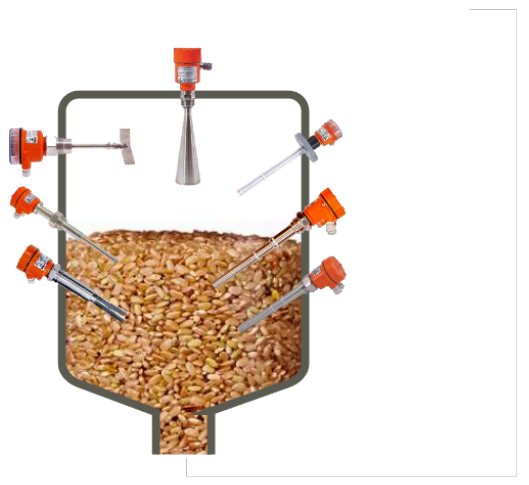

Application

Trumen LSR is used in different applications like-

- Powders & Granuals like Calcium carbonate, pvc powder, polyester chips, animal feeds etc.

- Process temperature maximum 200 degree C / 400 degree C (available on requirement).

- Operating pressure 3 bar maximum.

Calcium Carbonate

PVC Powder

Polyester Chips

Animal Feeds

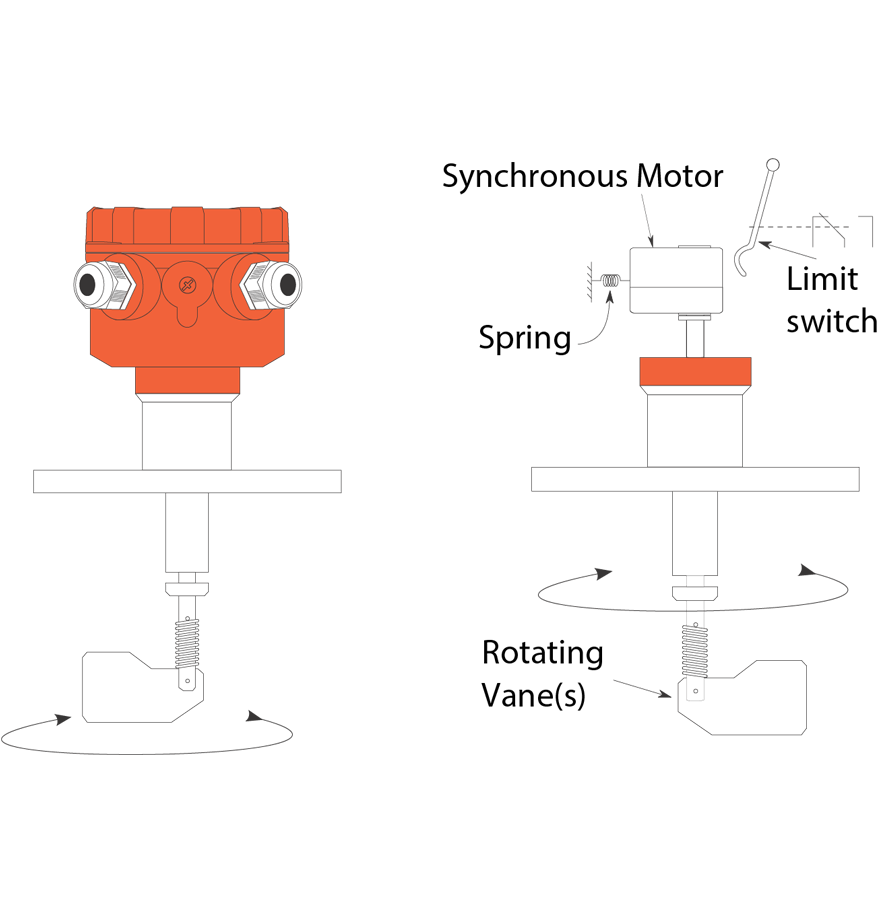

Operating Principle

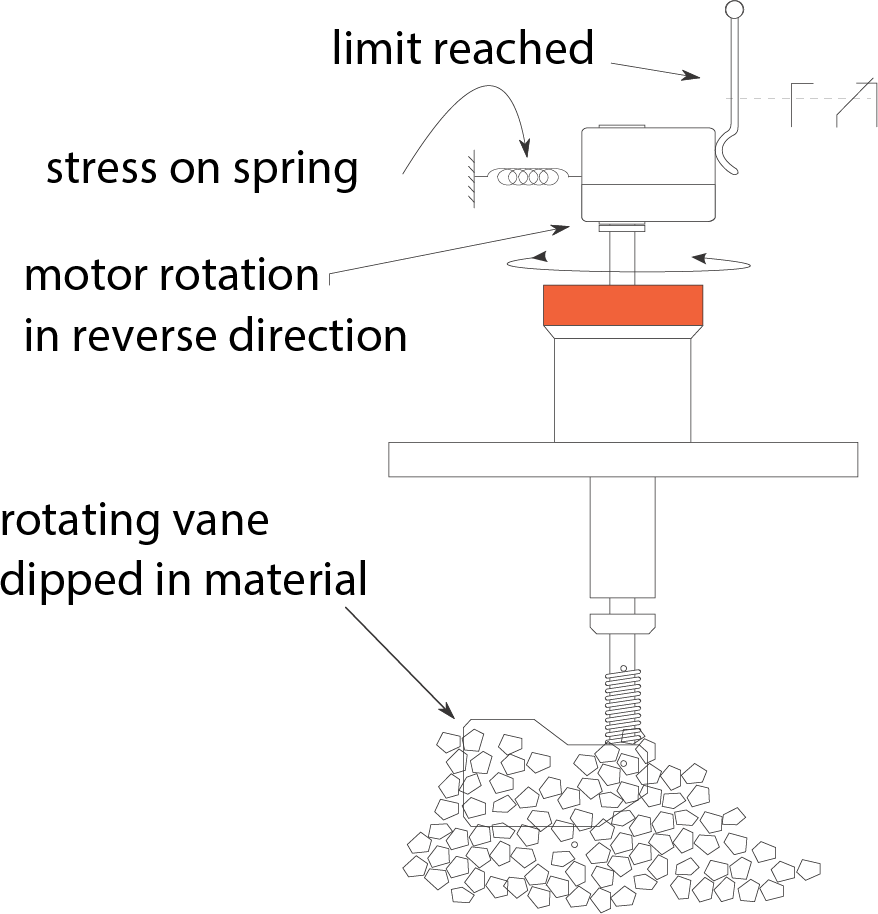

Rotating paddle level switches are basically a spring loaded, eccentricaly driven rotating vanes (or blades) which rotate at one revolution per minute, using an ac synchronous motor.

When no material is present, rotating vanes, (or blades or paddles) are free to move and motor is held by a spring in its normal position.

When material reaches the rotating vanes, it tries to stop the rotation of vanes, causing a reverse rotation of motor and stress on the spring which is holding the motor.

When motor rotates to a degree where limit switch is present, the power to motor is turned-off and output is generated.

As soon as material level falls, the vanes become free to rotate once again, causing the motor to turn back to its normal position due to stress on the spring holding the eccentric-drive, synchronous motor.